Among the more traditional olive farmers there is a belief associated with mechanized pruning of the olive grove that is rarely positive. However, there are already many farmers who carry out this type of pruning, and in high-density cultivation systems it is a task that fits in perfectly with its fundamentals.

That is why, in this article, we are going to talk about the basics of mechanizing such an important task as pruning and the different pruning operations that can be mechanized.

Why mechanization of pruning of hedgerow olive groves is so important?

High-density crops or hedgerow crops such as olive groves have very clear foundations:

- Mechanization of the work and reduction of labour.

- Early entry into production and high productivity

- Increased efficiency in the use of resources.

In the case of olive groves, pruning has traditionally been the most labour-intensive crop operation after harvesting. Nowadays, we are all aware of the problem of specialized labour in agriculture and the increase in production costs that the use of such labour currently entails compared to tasks that can be mechanized.

Pruning is one of the main tasks that an olive grower farmer should use to regulate production and have healthy and long-lasting plantations.

Aims of pruning in the olive grove

Pruning is one of the main tasks that an olive farmer should use to regulate production and have healthy and long-lasting plantations.

In the case of hedgerow or super-intensive olive groves we have to replace the old concept of the individual plant by the one of “continuous hedge” or “productive wall”, but the searched set of aims is the same as with the pruning of traditional olive groves:

– Directing the growth of the tree towards achieving a specific and appropriate shape.

– Generating a favorable microclimate that maximizes light interception, provides good ventilation and reduces shading.

– Achieving a good balance between vegetation and olive grove production.

– Obtaining a high production per unit area.

– MInimazing costs and labour.

NOTE: When carrying out any pruning intervention we must take into account the effects it will have on the present and future of the plantation (productivity and vegetative habit).

What are the consequences of mechanized pruning in hedgerow olive groves?

If one of the purposes of pruning is to help us to produce more fruit and in a more constant manner, we must be aware of the conditions in which the olive is produced.

Throughout its life, the tree goes through different phases or periods (formation, production, old age) and pruning has to adapt to them. That is why knowing the role played by the organs of this tree and the consequences that their removal can have is crucial.

As you know, the flower buds are usually located on the shoots that have grown during the previous year and, in turn, the tree’s growth in thickness and length is determined by the wood buds. Apart from that, the leaf is the fundamental organ for the functioning of the plant (energy generation and nutrition).

And this is one of the main aspects to take into account when pruning: “the maintenance of a correct relationship between the number of leaves and roots and the surface area of leaves and wood”.

We alternate these ratios when pruning and we must always keep them at high values close to the optimum.

How do pruning cuts influence the olive tree?

Pruning cuts can be made in two ways, either on a thick branch or on a thin branch by cutting it off in its entirety or by thinning it (undercut or thinning cut)

The thinning cut will improve the lighting of the branches, they will thicken and in turn grow laterally, improving nutrition, flowering and fruiting (also known as thinning).

In the case of undercut, the sprouting of buds in the preserved area is encouraged (also known as topping).

Both of these two methods help us in hedged olive groves to maintain an adequate productive structure and to keep the hedgerow at a suitable size for its correct management.

How does a tree react to pruning?

The first thing is always survival. And this is a key if we want to understand how crops behave when pruning because the olive tree has an extreme sensitivity, ensuring first its survival and then its production to go against these is to go against our own interests.

The pruning operation must always be conceived taking into account the natural tendency and the fact that the olive tree has the capacity to renew itself… which allows its constant rejuvenation through pruning.

A rationally trained olive tree produces hardly any “suckers” or adventitious branches and this is a clear manifestation of an unbalanced olive tree.

What factors influence the pruning of olive trees?

As all tasks, there are a series of factors that will determine how pruning it is carried out and which must be taken into account if we want to achieve the aims set out above.

– Age of the olive grove: we must clearly differentiate the different stages through which the olive grove passes in order to carry out the most appropriate actions (training pruning, production pruning, rejuvenation pruning).

– Soil and climate: the intensity of the pruning cuts will depend on the degree of development of the olive tree and this in turn is a consequence of how favorable the climate is for it and the fertility and quality of the soil.

– Variety: the growth habit and vigor of each variety is different, and therefore we will have to adapt the pruning actions to each one of them.

– Cultural practices: irrigation, weed management… all of these can and should help us to find a good vegetative-productive balance together with pruning.

– Pruning season: we can differentiate between winter pruning and summer pruning.

**In areas with late frosts, winter pruning should be delayed until early spring.

– Type of pruning and training system: as we increase our knowledge of the cultivation system, different training systems and the methods and machinery available for pruning also appear.

What types of pruning can be mechanized?

As the system has evolved, so have the resources available to the olive farmer, and today we have a variety of highly efficient pneumatic pruning equipment, which has allowed us to reduce the time taken to carry out the operations and allows us to say that “olive pruning is fully mechanized“.

This does not mean, however, that manual operations must occasionally be carried out to help us achieve the aforementioned aims (in fact, it would be more than advisable as machines are not yet able to discriminate between “good” and “bad” branches).

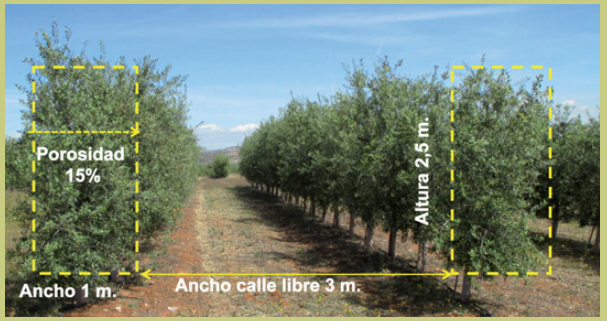

We must remember that in olive groves the conduction system will be limited by the use of grape harvesting machines, which will condition the size of the trees, which will have to be limited by pruning:

We can therefore differentiate between the following types of pruning/interventions:

– Lateral pruning with trimmer: during the periods of plant formation, in formation systems such as smartree, lateral pruning should be carried out when the branches reach a length of about 40 cm, slowing their growth and redirecting it towards branches in the direction of the planting line and branches growing in height, as the natural tendency of trees is to grow as a “balloon”. This will favor not only the formation of the plant but also its resistance to wind as the center of gravity will be low and the trunks will be thicker. The frequency of these trimming operations will depend on the speed of growth of the plantation.

To carry out this intervention in ID we have the PV-VIEW pre-pruning machine. This machine performs a clean scissor-type cut, generating less necrosis compared to other blades. It also works at speeds of up to 12km/h, and adapts to any plantation frame. PV-SETO, with a higher cutting power, is also among the range of blade pruners, for branches up to 3.5 cm in diameter.

– Lateral pruning with a disc machine: This technique is the one that fundamentally allows a severe labour reaction in the olive grove. It should be used once the productive structure of the olive grove has been formed, both in terms of height and length of the wall. It must be carried out during the months of vegetative standstill and avoiding frosts that could damage the wood. The tractor will move with the disc machine along the road at a constant speed, making the cuts parallel to the axis or with a slight inclination. The frequency of the cuts will depend on the degree of renewal of the tree and the expected production aims and strategy. It is important to note that at the end of a cycle of mechanised pruning (3-5 years) there is no loss in accumulated production, which is why it is becoming increasingly common on high-density crop farms. It can also be used to recover plantations affected by frost or severe attacks by glyphodes or to revitalise ageing plantations due to wide hedges or dry branches inside them.

– Height pruning or topping: the height of the plantation will be defined by the harvesting machine and should always be limited to between 2.5-2.9 m in height. To maintain the hedge at this height, topping pruning is carried out, which basically consists of using the cutting disc machine to lower the height of the olive grove at the moment we consider appropriate. This intervention can be carried out both in winter and during the summer months depending on the growth, aims and development of the plantation. To carry out this intervention in ID we have the V1 machine.

This pruning machine adapts to the needs of the farmer for lateral and crown pruning, from 0.75 in height. It makes a perfect cut using interchangeable discs for all types of branches. For higher performance we have V-DUAL, ideal for pruning two rows simultaneously, specially designed for large plantations.

– Pruning of low branches: in hedgerow olive groves, the branches that hang below the first 50-60 cm are a problem for various reasons (their production cannot be harvested, they prevent the scales from closing and they are a barrier to the application of herbicide). Nowadays, the elimination of these scales can be carried out very easily and quickly with mechanical weed trimmers, which are attached to the front part of the tractor and allow us to handle them very efficiently, and to carry out this task in ID we have OLIX. This new design has 60 centimetre diameter boron steel blades and an innovative turbine that sucks in the lower branches to make a perfect cut.

“Evolution is not a theory, it is a fact”.

It is clear that it is difficult to change the way in which the different tasks have traditionally been carried out in the olive grove, but we have to understand that cultivation systems are evolving and with it the tasks and machinery associated with them.

As you have seen, mechanized pruning in high density crops such as hedgerow olive groves is a task that fits in perfectly with the fundamentals of the same.

In future articles we will look in depth at how to carry out each of the different pruning interventions; do you join us?